Industrial environments demand network equipment that can deliver consistent power, high-speed data transmission and stability under physical and electrical stress. From manufacturing plants and transportation systems to defence, mining and outdoor surveillance, connectivity has to withstand much more than what traditional enterprise networks face. This is where industrial-grade Power over Ethernet (PoE) switches, especially those built with L3 capabilities, stand out as critical infrastructure elements.

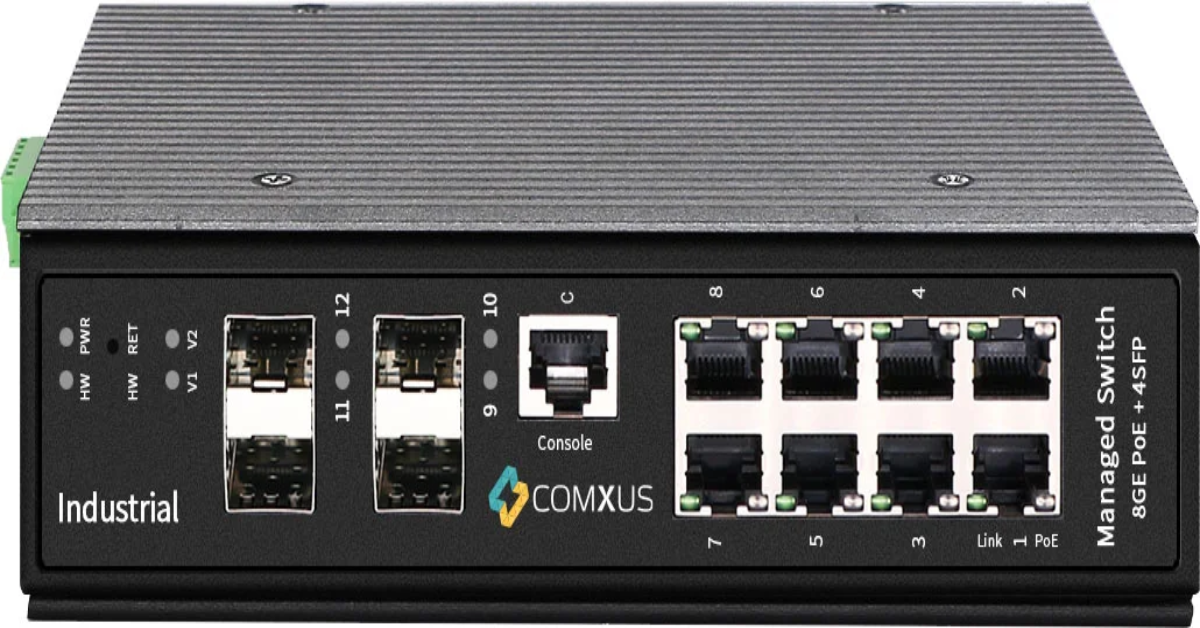

Using the Comxus 8 Port Industrial PoE Switch as an industry-specific example, this article explores how such switches maintain network reliability, efficiency and uptime in harsh environments.

Why Industrial Environments Require Specialised Network Switches

Unlike air-conditioned offices or controlled server rooms, industrial settings expose network hardware to conditions that can seriously degrade performance or cause failure. Here are key environmental and operational challenges:

1. Extreme Temperature Variations

Industrial-grade networks are often installed in oil rigs, outdoor substations, warehouses, railways and production lines. These areas may have:

- Temperatures ranging from -40°C to +75°C

- High humidity and condensation

- Direct sunlight or freezing conditions

Switches with industrial thermal design and wide temperature tolerance are necessary to maintain uptime.

2. Dust, Vibration and Shock

Factories, ports and construction zones can expose equipment to:

- Mechanical vibrations from heavy machines

- Fine particulates or dust

- Abrasive environmental contaminants

Enclosures with IP-rated protection, fanless cooling and shock-resistant internal components extend longevity.

3. Electrical Noise and Power Instability

Industrial power grids often suffer from:

- Voltage fluctuations

- Electromagnetic interference (EMI)

- Grounding inconsistencies

Resilient circuit protection, surge resistance and galvanic isolation are critical for safe operation.

4. Extended Cable Distances and Device Density

Industrial setups commonly power IP cameras, sensors, VoIP devices and access points over long cables. PoE reduces wiring complexity but demands stable voltage and power budgeting.

An industrial PoE switch with Layer 3 capabilities offers both continuity and segmentation, ensuring seamless connectivity across distributed networks.

Features of an L3 Industrial-Grade PoE Switch

The Comxus 8 Port L3 PoE switch used as an industry benchmark illustrates how a device can combine data routing, power delivery and ruggedness into one platform.

Feature #1: Layer 3 Routing for Scalable Network Design

A Layer 3 (L3) switch provides:

- Static routing

- VLAN-to-VLAN communication

- Inter-network segmentation

- Broadcast domain control

These capabilities ensure that networks used in large industrial campuses, transportation grids and security systems remain efficient and organised.

Feature #2: PoE and PoE+ Power Support

Industrial PoE switches typically support:

- IEEE 802.3af (PoE): Up to 15.4W per port

- IEEE 802.3at (PoE+): Up to 30W per port

An 8-port model allows centralised power distribution to devices like:

- IP surveillance cameras

- Wireless access points

- Environmental sensors

- VoIP telephones

- Access control systems

This eliminates the need for separate electrical outlets and reduces infrastructure costs.

Feature #3: Rugged Housing and Thermal Design

Industrial-grade switches typically feature:

- Metal enclosures for heat dissipation

- DIN-rail or wall mounting compatibility

- Fanless cooling systems

- Protection against dust and moisture

These characteristics support uninterrupted operation even in confined, unventilated spaces.

Feature #4: Redundant Power Inputs

To ensure reliability during power failures, industrial PoE switches may support:

- Dual DC power inputs

- Surge protection

- Automated failover mechanisms

This prevents data loss and device downtime during sudden outages.

Feature #5: Network Security and Management

Advanced security ensures that automation systems and digital assets remain protected:

- DHCP snooping

- Port protection

- Access Control Lists (ACLs)

- 802.1X authentication

- VLAN support

- SNMP and Web UI configuration

These configurations allow IT and OT teams to maintain visibility and control over critical infrastructure.

How Industrial PoE Switches Ensure Reliability in Harsh Environments

The performance of a rugged PoE L3 switch depends on a combination of mechanical endurance, network design, and smart management.

1. Wide Operating Temperature Range

A typical enterprise switch may only function between 0°C and 40°C. In contrast, industrial models often support a thermal range of -40°C to +75°C. This allows outdoor installations on poles, roadside cabinets, parking lots and industrial shelters.

Switches like the 8-port L3 PoE model referenced here use:

- Heat-resistant circuit boards

- Conformal coating on components

- High-efficiency heat sinks

- Fanless passive cooling

These design elements reduce the number of moving parts and eliminate potential failure points.

2. Enhanced Surge and ESD Protection

Industrial networks are exposed to:

- Lightning surges

- Static interference

- Voltage spikes

Surge-protected ports and power inputs reduce the impact of such events. Isolation features prevent damage from ground loops or faulty wiring.

3. Managed Redundancy and Failover

Critical networks such as emergency systems, defence setups, or traffic monitoring cannot afford downtime. L3 switches provide redundant pathways using:

- Rapid Spanning Tree Protocol (RSTP)

- ERPS (Ethernet Ring Protection Switching)

- VRRP (Virtual Router Redundancy Protocol)

This ensures uninterrupted connectivity even when one link fails.

4. Advanced PoE Power Management

PoE budgeting is vital to avoid overload and ensure that key devices receive an uninterrupted supply. Smart industrial switches include:

- Port prioritization

- Per-port power monitoring

- Overload prevention

- Remote reboot capabilities

This is especially useful in sites with cameras, alarms, and wireless endpoints.

5. Vibration-Proof Mechanical Design

In locations such as railway depots, mining areas and assembly lines, switches are subject to constant vibration. Industrial switches employ:

- Strengthened PCB mounting

- Locking terminals

- High-grade internal wiring

- Shock-absorbing enclosures

These measures preserve both port integrity and long-term reliability.

Application Scenarios

Below are some typical environments where a rugged 8-port L3 PoE switch proves valuable.

Transportation and Traffic Management

- Roadside surveillance networks

- Smart traffic lights and signals

- Highway emergency systems

- Railway communications

These spaces demand constant uptime, resistance to temperature extremes and secure routing.

Oil and Gas Facilities

Remote pumping stations and offshore platforms often operate under corrosive, high-risk or extremely hot conditions. Industrial switches ensure:

- Long-distance PoE connectivity to sensors

- Layer 3 network segmentation

- Support for explosion-proof enclosures

Manufacturing Plants and Warehouses

Automated machinery relies on stable communication between PLCs, SCADA systems and monitoring equipment. PoE reduces cabling while L3 routing ensures efficient traffic routing across departments.

Outdoor Surveillance and Security

Perimeter monitoring, parking lots and smart city infrastructure rely on powered IP cameras and access points placed at long distances. A rugged PoE switch helps reduce maintenance and downtime.

Renewable Energy Sites

Wind farms, solar plants and hydropower stations are often spread across wide areas. Switches connect controllers, sensors and monitoring stations without climate control rooms.

Advantages of Using Layer 3 Industrial PoE Switches

1. Reduced Downtime

Harsh conditions can cause regular equipment to fail quickly. Industrial switches extend device lifespan and eliminate frequent replacements.

2. Consolidation of Power and Data

Using one cable for both power and communication reduces complexity and installation time.

3. Better Network Segmentation

L3 functionality allows separate VLANs for different departments, reducing congestion and improving traffic flow.

4. Remote Monitoring and Configuration

Through SNMP, Telnet, CLI or web UI, network administrators can update, troubleshoot and reboot devices remotely.

5. Cost Savings on Infrastructure

Eliminating extra power supplies, UPS units and patch panels helps reduce long-run expenses.

Compliance and Certifications in Industrial Networking

A switch used in harsh zones must meet global standards. Many industrial-grade devices, including those similar to the Comxus 8-port model, comply with:

- IEEE 802.3, 802.1Q, 802.1w

- IP30 / IP40 / IP54 enclosure ratings

- CE, FCC, UL, and EMC certifications

- RoHS for environmental compliance

- EN50155 / IEC 61850 for transportation and utility sectors

If the switch is mounted in outdoor cabinets or near explosive zones, ATEX and NEMA ratings may also apply.

Installation and Deployment Considerations

Deploying an industrial-grade L3 PoE switch typically involves:

Step 1: Environmental Assessment

Determine:

- Ambient temperature

- Power availability

- Cable distances

- Exposure to water, dust, or vibration

Step 2: Network Planning

Define:

- VLAN requirements

- PoE power allocation

- Redundant routing paths

- Traffic segregation between IT and OT devices

Step 3: Mounting and Power Configuration

A DIN-rail or wall mount setup may be used, depending on cabinet design and airflow needs. Dual power feeds should be connected if redundancy is required.

Step 4: Device Integration

Connect PoE endpoints such as:

- Cameras

- Wireless access points

- IoT gateways

- Smart sensors

Configure routing, VLANs and security policies.

Step 5: Monitoring and Maintenance

Use SNMP or web dashboards for:

- Power budgeting

- Port status

- Packet flow statistics

- Failure notifications

Future Trends in Industrial PoE and Networking

As industries modernise, new requirements are emerging:

PoE++ and Higher Power Budgets

IEEE 802.3bt allows up to 90W per port, enabling the connection of high-power PTZ cameras and industrial computers.

Edge Computing and AI Integration

Switches with enhanced processing may support local data filtering and real-time analytics.

Cybersecurity Reinforcement

With increasing automation and remote access, features like zero-trust access, ACLs and deep packet inspection are becoming more common.

10G and Multi-Gig Uplinks

Bandwidth-intensive setups like digital surveillance demand faster backbones.

IPv6 and IoT Scalability

Future-ready switches will accommodate millions of connected devices through Layer 3 routing and extended addressing.

Note: Industrial-grade PoE switches with Layer 3 capabilities play a vital role in ensuring network uptime, powering remote devices and maintaining efficient traffic flow in challenging environments.

From extreme temperatures and electrical interference to secure data routing and real-time device monitoring, these switches form the backbone of operational technology (OT) networks. Organisations across manufacturing, transportation, utilities and energy sectors benefit from their rugged construction, intelligent power management and multi-layer networking capabilities.